Precision Alignment

At Madge USA, we understand that production is crucial to maintaining competitiveness in the rolling mill industry. Poor alignment can lead to reduced rolling speeds, causing significant financial losses. That’s why we offer top-of-the-line measuring and alignment services to ensure your equipment operates at optimal performance.

With every alignment job, we always include a comprehensive mill housing inspection. This ensures that we identify any potential imperfections or issues, providing you with a complete assessment of your equipment's condition. Our goal is to ensure that not only is your mill properly aligned but that it operates at its best for long-term efficiency and reliability.

When aligning new mills, we can achieve an impressive tolerance of (0.001 in) or better. This precision ensures your mill operates at peak performance, maximizing both production efficiency and product quality. By maintaining such tight tolerances, we help you achieve superior results and reduce the risk of defects, ultimately boosting your bottom line.

- Measure and Report: If you want to assess whether your mill is properly aligned, we’ll measure and provide a detailed report on its current condition.

- Measure and Fix: If your mill has been experiencing issues, we’ll not only measure but also work with your team or provide the labor and materials adjust your equipment targeting the original tolerances.

For older equipment, we offer two comprehensive services to suit your needs:

Completed Mill Projects by Madge USA

Successfully aligned two 20-high reversing mills at 52” width, ensuring optimal strip flatness and uniformity.

Completed precision alignment for three 26” wide 20-high reversing mills, used for high-precision rolling operations.

Performed comprehensive measurement and correction of a single 14” wide 20-high reversing mill.

Conducted precision alignment on three compact 4” wide 20-high reversing mills.

Aligned five 18” wide 20-high reversing mills, optimizing roll parallelism and stability.

Dual-width 20-high reversing mill (12” & 17”) aligned for versatile rolling applications.

Completed alignment on two 18” wide 4-high rolling mills, used for precision cold rolling.

Choose Madge USA for unmatched rolling mill measurement and alignment

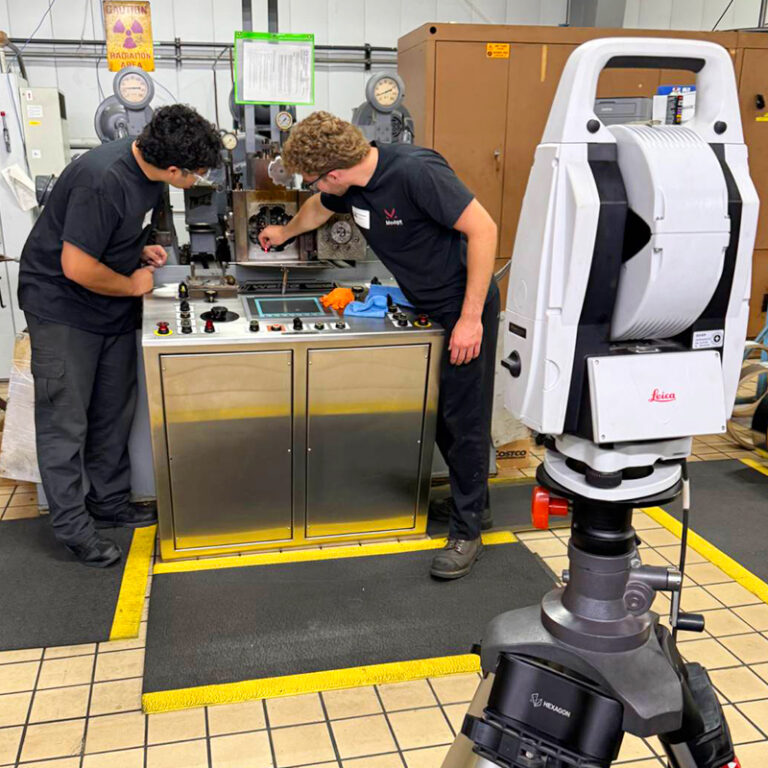

When precision matters, Madge USA is your only choice for rolling mill alignment. Leveraging state-of-the-art laser alignment technology, we provide unparalleled accuracy and efficiency, ensuring your equipment operates at its optimal performance.

Our advanced laser systems offer real-time, highly precise measurements that eliminate the guesswork, reduce costly downtime, and extend the lifespan of your machinery. At Madge USA, we understand that proper mill alignment is crucial to maximizing production, minimizing operational costs, and enhancing overall productivity.

While many companies can measure rolling mills, only Madge USA can correct them. Our experienced team of specialists is dedicated to delivering exceptional service using the latest tools and techniques to keep your rolling mills running smoothly, efficiently, and cost-effectively.

For precision, reliability, and expertise in laser alignment, trust Madge USA to optimize your rolling mill.